El País

“AEF freezing is not only faster than the traditional approaches, but, moreover, acoustic waves of AEF technology prevent cell disruption, being inevitable until now.”

AEF EQUIPMENT GENERATES ACOUSTIC WAVES THAT FORM NANO-SIZED ICE CRYSTALS AND PROTECT FROM THE IMPACT OF THESE FACTORS.

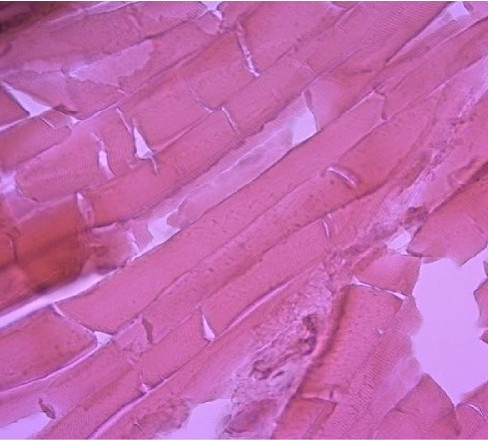

Defrosted beef after three months of storage

AEF freezing (right) and traditional freezing (left)

DIAGRAM OF TEMPERATURE DECREASE IN THE CENTER.

Diagram degrees/minutes. Temperature in the chamber: -36C°. AEF AERO.

Samples of 10 and 13 cm (orange, blue) in open cardboard box.

Samples of 10 and 13 cm (yellow, grey) in vacuum packaging.

AEF TECHNOLOGY

Acoustic waves do not generate cold, but influence on incipient ice crystals;

AEF technology is intended for application in combination with industrial freezing chambers and tunnel freezers, including spiral freezers;

AEF technology comprises of:

- equipment – acoustic radiators, electronic boards;

- software – product-specific freezing protocols for different types of products;

- 3-D CAD for power optimization and directing of acoustic and air waves within the chamber.

Abat 20 AEF / AEF + AEF-AERO for spiral chamber / AEF + AEF-AERO in the freezer.

PROGRESS AND ACTUAL STATUS

2018 - AEF equipment obtained CE certificate of the EC;

2018 - AEF technology was introduced at Seafood Expo North America - 2018 in Boston, the USA;

As of October 1, 2021 more than 120 units of AEF equipment (15 units – resale) were sold in 27 countries;

Product tests and negotiating with the key customers such as HIPP, Danone, Fazer, Nord Frost and others are in progress;

The technology obtained PCT international patent;

It has been included in Global FoodTech 500 starting from 2020.

AEF exhibit booth at Seafood Expo North America. Boston, USA. March 2018.

COMPETITIVE DECISION – CAS

AEF – is a world-unique digital freezing technology that uses different product-specific freezing protocols for different types of products;

A well-known “shock freezing” was invented more than hundred years ago and has not been improved a lot since then. This approach had long been obsolete. The best results in pork freezing – thawing loss of 4.5% and grade deterioration. Acoustic technology – thawing loss of 1.5% and maintenance of grade.

CAS freezing technology from Japan: a single freezing protocol, the equipment is 4 times more expensive than AEF.

DEFROSTED FLORENTINE STEAK HAS THE SAME TASTE AS FRESH ONE

Defrosted steak after AEF freezing (left) and fresh meat (right). Antica Trattoria la Torre – a family-owned restaurant with 127-year history.

LIGHT FREEZING OF BACON AND SAUSAGES BEFORE CUTTING – A TOTAL ABSENCE OF LIQUID INSIDE THE PACKAGING, ZERO LOSS (0%)

Left – a bacon before freezing. Right – a bacon after freezing up to -7°C from every side and cutting.

HAMBURGERS AFTER AEF FREEZING HAVE BETTER TASTE THAN FRESH ONES

Defrosted AEF burger before cooking for blind test. Mercamadrid Market. Spain.

STANDARD CHAMBERS FOR AEF ACOUSTIC FREEZING

A standard chamber for AEF acoustic freezing with a capacity of 2 tons a day.

Price: 63 200 EUR

A standard chamber for AEF acoustic freezing with a capacity of 3 tons a day.

Price: 69 500 EUR

A standard chamber for AEF acoustic freezing with a capacity of 5 tons a day.

Price: 97 300 EUR

A standard chamber for AEF acoustic freezing with a capacity of 10 tons a day.

Price: 151 700 EUR

Comments